Open Slot Mortise And Tenon Joint

- Through Mortise And Tenon Joint

- Angled Mortise And Tenon Joints

- Open Slot Mortise And Tenon Joint System

- Open Slot Mortise And Tenon Joint Machine

- Open Slot Mortise And Tenon Joint Pain

A mortiser or morticer is a specialized woodworkingmachine used to cut square or rectangular holes in a piece of lumber (timber), such as a mortise in a mortise and tenon joint.

Square chisel mortiser[edit]

Last week I talked about How To Cut Tenons on a Table Saw, but a tenon isn’t much good without a mortise to fit into.So, this week I’ll show you the easy way to make mortises. Like all things in woodworking, there are several ways to do this, but in my opinion, this technique is by far the easiest and most consistent.

- Mortise And Tenon Joint Advantages Mortise & Tenon is used generally when corner joints need to have sturdy frames for making things such as doors, tables, windows, and beds. A rectangular slot is referred to as a Mortise cut, and it is cut into the (exact) center of the end piece of wood so that it will except the protuberance fitting (the.

- The mortise and tenon woodworking joint has been used around the world for thousands of years—for good reason. It's considered one of the strongest woodworking joints for attaching two pieces of.

The square chisel mortiser (also called hollow chisel mortiser), similar to a drill press in many respects, combines the cutting of a four-sided chisel with the action of a drill bit in the center. The bit clears out most of the material to be removed, and the chisel ensures the edges are straight and clean. This device was invented in 1874 by Robert and Ralph Greenlee (founders of the Greenlee Company).

The first square chisel lever mortisers were purely manual and relied on the operator pulling down on a large lever to push the chisel through the timber. An improvement was to place a rotating cylindrical auger inside a hollow chisel. This helps to clear chips up the centre of the chisel. As electric power became easily available, the auger developed as a drill bit and became the main means of removing waste timber from the mortise. These mortisers now used much shorter hand levers, as the manual work was only in cleaning up the mortise to be square-cornered.

Square chisel mortising bits can also be fitted to normal drill presses using a mortising attachment.

The Greenlee Company still manufactures mortisers, as do a large number of other power toolmanufacturers. It is a common tool in the woodshop of professional woodworkers, but because of its specialized nature, many amateur woodworkers would not make enough use of it to justify the moderately high cost and space this tool takes up in the woodshop. Some smaller and less expensive models, suitable for cutting only narrow mortises are available.

Horizontal mortiser (slot mortiser)[edit]

A more recent innovation is the horizontal mortiser, which incorporates a router mounted statically on its side with the workpiece clamped to a multi-axis sliding table. This type of mortiser can produce either traditional mortise and tenon pairs, however it excels at floating (or 'loose') tenons. A floating tenon is where both the pieces of wood that are to be joined have aligned mortises cut into them and a separate piece of wood is milled into a fitted tenon which is glued into the two mortises.

Chain mortiser[edit]

For cutting larger mortises such as those used in timber frame construction, chain mortisers are commonly used. A chain with cutters (similar to a chainsaw chain) rotating within a frame clamped to the work is successively plunged into the workpiece to mortise out the required volume. The Makita 7104L is such a tool. These chains are made in varying widths, with numbers of chains in parallel. The teeth are often solid or tipped tungsten carbide. They are thus very expensive, sometimes as much as the rest of the mortiser.

Other methods of cutting mortises[edit]

Traditionally, a mortise would be cut by hand, using a chisel and mallet. However, due to the precision of fit required for a mortise and tenon joint, this can be a difficult and time-consuming task.

Other tools such as a router could be used for the task, but the router usually requires special attachments, jigs or templates and the router bit leaves rounded corners that might need to be squared by hand with a chisel. Alternatively, the tenon can be rounded with a rasp to achieve an equally strong joint.

For cutting small mortises, a normal drill bit can be used. However, for larger mortises, a common type of bit in modern mortisers is a Harry Watt square drill bit, in which a bit with a Reuleaux triangle cross section is allowed to 'wobble' while it rotates within a square with rounded corners[citation needed]. This type of bit removes all but the corners of the material to be removed, leaving very little to be cut by the chisel.

Through Mortise And Tenon Joint

See also[edit]

- Rotary broaching, a method of drilling square holes in steel.

External links[edit]

- History of the Greenlee Company - includes the history of the mortiser

- Reuleaux triangle on MathWorld - includes an animation of the action of a Harry Watt square drill bit

A mortise (or mortice) and tenonjoint connects two pieces of wood or of other material. Woodworkers around the world have used it for thousands of years to join pieces of wood, mainly when the adjoining pieces connect at right angles.

In its most basic form, a mortise and tenon joint is both simple and strong. There are many variations of this type of joint, but the basic mortise and tenon comprises two components:

- the mortise hole, and

- the tenon tongue.

The tenon, formed on the end of a member generally referred to as a rail, fits into a square or rectangular hole cut into the other, corresponding member. The tenon is cut to fit the mortise hole exactly. It usually has shoulders that seat when the joint fully enters the mortise hole. The joint may be glued, pinned, or wedged to lock it in place.

This joint is also used with other materials. For example, it is traditionally used by both stonemasons and blacksmiths.

- 3Types

Etymology[edit]

The noun mortise, 'a hole or groove in which something is fitted to form a joint,' comes from c. 1400 from Old Frenchmortaise (13th c.), possibly from Arabicmurtazz, 'fastened,' past participle of razza, 'cut a mortise in.'[1]

The word tenon, a noun in English since the late 14th century, developed its sense of 'a projection inserted to make a joint' from the Old French tenir 'to hold.'[2]

History and ancient examples[edit]

This is an ancient joint dating back 7,000 years. The first examples, tusked joints, were found in a well near Leipzig - the world's oldest intact wooden architecture.[3] It has also been found joining the wooden planks of the 'Khufu ship',[4] a 43.6 m long vessel sealed into a pit in the Giza pyramid complex of the Fourth Dynasty around 2500 BC. The oldest known use dates from the Early Neolithic Linear Pottery culture, where it was used in the constructing of the wooden lining of water wells.[5]

It has also been found in ancient furniture from archaeological sites in the Middle East, Europe and Asia. Many instances are found, for example, in ruins of houses in the Silk Road kingdom of Cadota, dating from the first to the fourth century BC.[6] In traditional Chinese architecture, wood components, such as beams, brackets, roof frames and struts, were made to interlock with perfect fit, without using fasteners or glues, enabling the wood to expand and contract according to humidity.[7] Archaeological evidence from Chinese sites shows that, by the end of the Neolithic, mortise-and-tenon joinery was employed in Chinese construction.[8]

The thirty sarsen stones of Stonehenge were dressed and fashioned with mortise-and-tenon joints before they were erected between 2600 and 2400 BC. English Heritage - Building Stonehenge

Types[edit]

Mortises[edit]

A mortise is a cavity cut into a timber to receive a tenon. There are several kinds of mortise:[9]

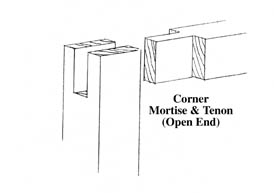

- Open mortise

- a mortise that has only three sides. (See bridle joint).

- Stub mortise

- a shallow mortise, the depth of which depends on the size of the timber; also a mortise that does not go through the workpiece (as opposed to a 'through mortise').

- Through mortise

- a mortise that passes entirely through a piece.

- Wedged half-dovetail

- a mortise in which the back is wider, or taller, than the front, or opening. The space for the wedge initially leaves room to insert the tenon. The wedge, after the tenon is engaged, prevents its withdrawal.

- Through-wedged half-dovetail

- a wedged half-dovetail mortise that passes entirely through the piece.

Tenons[edit]

A tenon is a projection on the end of a timber for insertion into a mortise. Usually the tenon is taller than it is wide. There are several kinds of tenon:

- Stub tenon

- short, the depth of which depends on the size of the timber; also a tenon that is shorter than the width of the mortised piece so the tenon does not show (as opposed to a 'through tenon').

- Through tenon

- a tenon that passes entirely through the piece of wood it is inserted into, being clearly visible on the back side.

- Loose tenon

- a tenon that is a separate part of the joint, as opposed to a fixed tenon that is an integral part of one of the pieces to be joined.

- Biscuit tenon

- a thin oval piece of wood, shaped like a biscuit[10]

- Pegged (or pinned) tenon

- the joint is strengthened by driving a peg or dowel pin (treenail) through one or more holes drilled through mortise side wall and tenon;[11] this is common in timber framing joints

- Tusk tenon

- a kind of mortise and tenon joint that uses a wedge-shaped key to hold the joint together.

- Teasel (or teazle) tenon

- a term used for the tenon on top of a jowled or gunstock post, which is typically received by the mortise in the underside of a tie beam. A common element of the English tying joint.

- Top tenon

- the tenon that occurs on top of a post.

- Hammer-headed tenon

- a method of forming a tenon joint when the shoulders cannot be tightened with a clamp.

- Half shoulder tenon

- An asymmetric tenon with a shoulder on one side only. A common use is in framed, ledged and braced doors.

Angled Mortise And Tenon Joints

Further details about the completed joint[edit]

Generally, the size of the mortise and tenon is related to the thickness of the timbers. It is good practice to proportion the tenon as one third the thickness of the rail, or as close to this as is practical. The haunch, the cut-away part of a sash corner joint that prevents the tenon coming loose, is one third the length of the tenon and one sixth of the width of the tenon in its depth. The remaining two-thirds of the rail, the tenon shoulders, help to counteract lateral forces that might tweak the tenon from the mortise, contributing to its strength. These also serve to hide imperfections in the opening of the mortise.

Gallery of various mortises[edit]

A traditional through, wedged, mortise and tenon joint

A stub tenon corner joint

A haunched stub tenon corner joint

A foxtail wedged tenon joint

A pinned corner tenon joint

A modern feather tenon joint (primarily called a loose tenon)

Open Slot Mortise And Tenon Joint System

See also[edit]

References[edit]

Open Slot Mortise And Tenon Joint Machine

- ^Harper, Douglas. 'mortise'. Online Etymology Dictionary. Retrieved 2019-02-19.

- ^Harper, Douglas. 'tenon'. Online Etymology Dictionary. Retrieved 2019-02-19.

- ^'The Neolithic Toolkit'. Archaeology.org. Retrieved 7 January 2015.

- ^Ward, Cheryl. 'World's Oldest Planked Boats,' in Archaeology (Volume 54, Number 3, May/June 2001). Archaeological Institute of America.

- ^Early Neolithic Water Wells Reveal the World's Oldest Wood Architecture Tegel W, Elburg R, Hakelberg D, Stäuble H, Büntgen U (2012) Early Neolithic Water Wells Reveal the World's Oldest Wood Architecture. PLoS ONE 7(12): e51374. doi:10.1371/journal.pone.0051374

- ^Roberts, Rachel (2012). 'House-building in Ancient Niya'. IDP News. 39. Retrieved 26 October 2012.

- ^Steinhardt, Nancy W. (2002). Chinese Architecture (English ed.). Yale University Press. p. 1. ISBN978-0-300-09559-3.

- ^Xujie, Liu (2002). Chinese Architecture - The Origins of Chinese Architecture (English ed.). Yale University Press. p. 11. ISBN978-0-300-09559-3.

- ^Dekker, Michael. 'Mortise-and-Tenon'. Woodwork Details. Retrieved 2015-02-18.

- ^'Our Reviews, Your Decision'. Man Of Family. Retrieved 2017-07-28.

- ^Teague, Matthew (May 2007). 'The Pegged Joint, Exposed'. Fine Woodworking. Taunton Press. Retrieved 2015-02-18.

- This article is partly based on a Quicksilver wiki article at A Glossary of Terms For Traditional Timber Framing (Timberbee) under the terms of the GNU Free Documentation License.